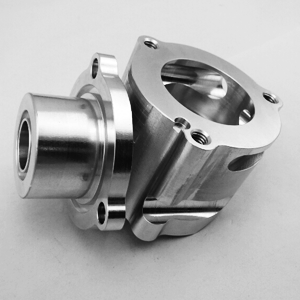

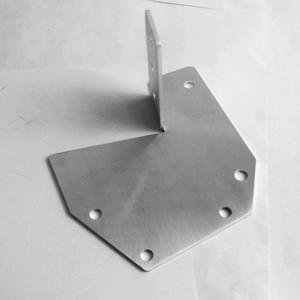

CNC machining service is the core business of Henrong precision manufacturing group, from 1 piece prototyping to series bulk production, our professional 3/4/5 aixs CNC machining centers, CNC turning equipments, CNC turning-milling equipments, CNC grinding machines etc., are operated by well trained manufacturing engineers to meet the demands from global 1600+ customers in 36+ industries.

Compared to other manufacturing solutions, CNC machining service has below obvious advantages:

1. High manufacturing precision.

CNC machining can reach 0.01mm manufacturing accuracy, and CNC grinding can reach 0.001mm manufacturing accuracy. The high manufacturing precision is well ensured by our professional industrial level CNC machining facilities and professional engineers with rich experience on CNC machining.

2. Smooth surface.

The high speed turning or milling can get smooth component surface after cutting the material, especially for CNC turning, if customer has special requirement, factory can get Ra 1.6 or better surface smoothness with none / raw finish. If customer doesn’t like the tooling marks on the surface of raw CNC machined surface, we can add finish like polish etc. to make the surface even smoother.

3. Flexible manufacturing volume.

CNC machining service does not need to make any mold in advance, so it is friendly for flexible manufacturing quantities from 1 piece prototyping to millions of pieces bulk production. We have established efficient flexible manufacturing system to better support customer’s demand on flexible quantity custom parts manufacturing.

4. Wide range of available materials.

CNC machining service is workable for all the machinable materials in theory, including aluminum, titanium, stainless steel, copper, brass, machinable plastic etc., CNC machining service is widely used because this manufacturing technology can well support very wide range of materials.

For quality inspection, we can provide professional material analysis report and component quality testing report as per customer’s specific requirements. Our professional quality inspection engineers carefully check every detail of the component, by industrial QC devices & tools, including international standard thread gauge, CMM, precision caliper, height gauge etc., we are committed to providing top quality CNC machining service with reasonable cost for global customers.