What is Dimension Tolerance?

Tolerance is an important technical data for machining. It always affects the products quality, process, quality testing, manufacturing cost and final products assembly etc.. For machining, tolerance is the allowable variation of geometric parameter values. To ensure that the variation of the geometric parameters of the product is within a certain range, it was formulated the demand of tolerance, so as to meet the requirements of interchange and assembly.

1. Basic Dimension

The dimension was given at design time, it is basic dimension.

2. Actual Dimension

The dimension is measured after completing production, it is actual dimension.

3. Limiting Dimension

The two limiting dimension that are allowed variation for the actual dimension, is limiting dimension. The larger one is Maximum limit size, that is Dmax; and the smaller one is minimum limit of size, that is Dmin.

For example:

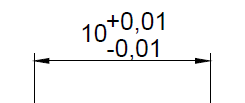

The basic dimension is 10mm

Dmax = 10+0.01= 10.01mm

Dmin = 10 – 0.01= 9.99mm

It marked as below:

And there is marked general tolerance as below table:

For the unmarked any tolerance items, we also follow below tolerance standard:

Unmarked linear dimension tolerance of hole diameter follows 0,+0.05mm.

The other unmarked linear dimension tolerance follows +/-0.05mm.

The unmarked non-linear dimension (angular, flatness etc.) tolerance follows ISO2768-MK.

Leave a Reply

Want to join the discussion?Feel free to contribute!