What is Tolerance?

1. Dimension Tolerance.

It is the allowable variation of the dimension, the absolute value of the difference between the allowable upper limit size and the minimum limit size. Or it is the value of the allowable upper deviation minus the lower deviation. Based on the same basic size, the smaller the dimensional tolerance, the higher the dimensional accuracy.

2. Geometric Tolerance.

It is used to mark the requirements of the form and position. It includes form tolerance and position tolerance.

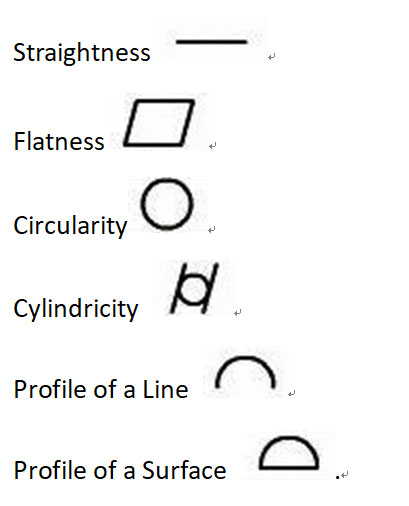

1) Form Tolerance.

It is the total amount of variation allowed by the shape of a single actual element. It includes 6 items:

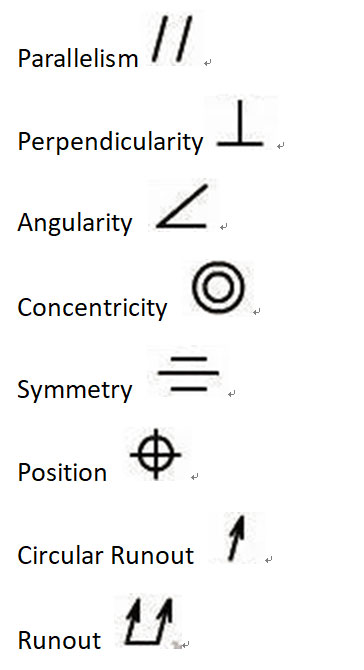

2) Position Tolerance.

It is the total amount of variation allowed by the position of the actual element to the reference, which limits the mutual positional relationship between two or more points, lines, and face of the part. It includes 8 items:

Leave a Reply

Want to join the discussion?Feel free to contribute!